Galvano-forming Components

Products

Take a closer look at what we can do for you. If you have any questions or suggestions, do not hesitate to contact us. We thrive to make possible what others deem impossible.

The following is a partial list of recurring products.

Our customers

Take a Look

Procedures

Typical applications and processes are described here. The list is not exhaustive. Contact us if you have any questions about further applications.

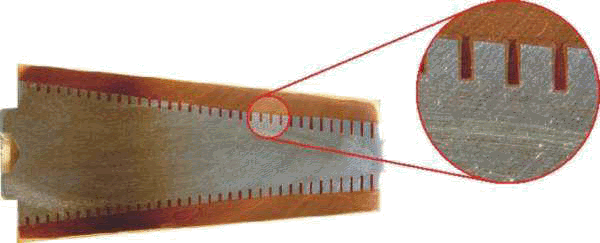

Thin-Walled Structures

Thin-walled components of 0,5 mm or less are challenging to process in mechanical manufacturing. Electroplating, however, provides a simple procedure that creates thin-walled structures without hassle.

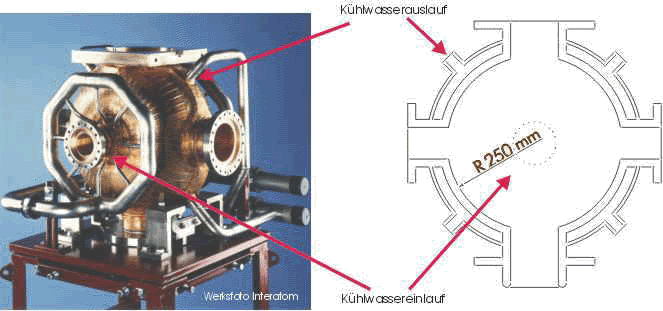

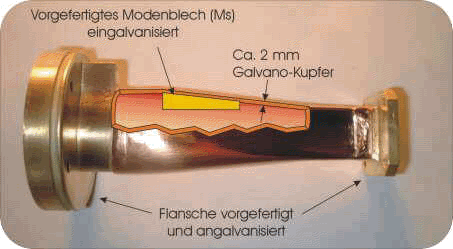

Variable Cooling Systems

Manufacturing cooling systems by employing the means of electro-plating has many advantages and allows the crafting of complex structures in many different renditions.

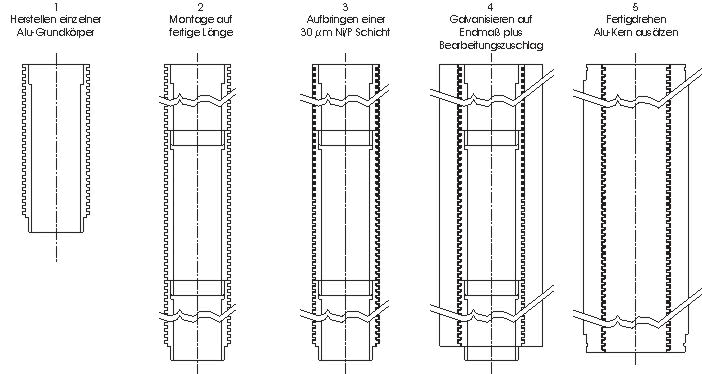

The Use of Cores in Galvano-Forming

Applications of cores in galvano-forming are manifold and especially interesting when conventional methods hit a technical or economical wall.

Galvano-T materials

Mainly copper and nickel are of interest for our processes.

Copper

Nickel

Contact us

Let us know your questions and we’ll be happy to get back to you